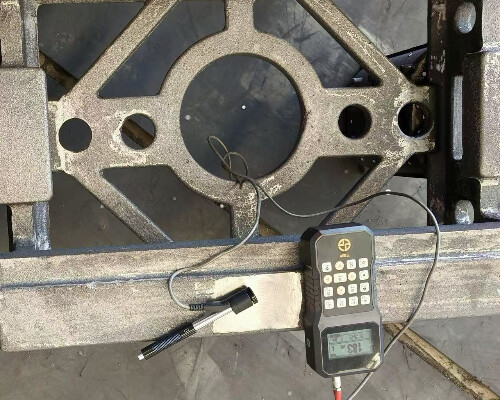

We use high-hardness gray iron to make molds, and use high-precision machining centers to process molds, which can ensure that the accuracy error of the product is 0.5MM, and the mold can be used more than 100,000 times. Suitable for making products with high precision and small weight.

SERVICE

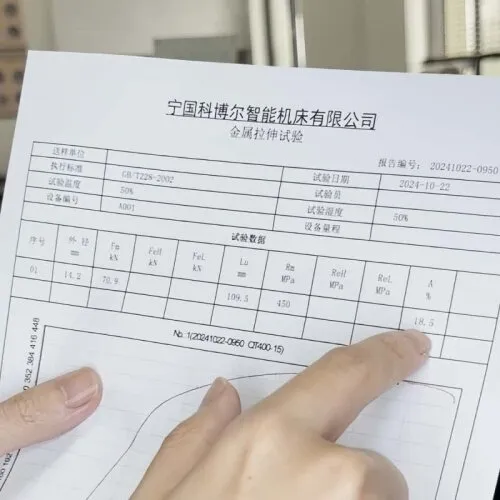

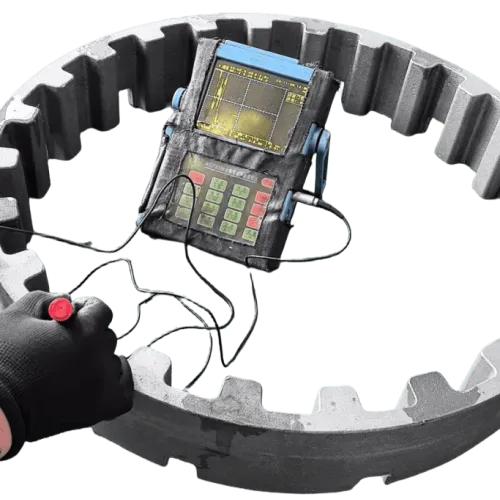

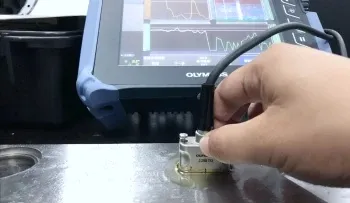

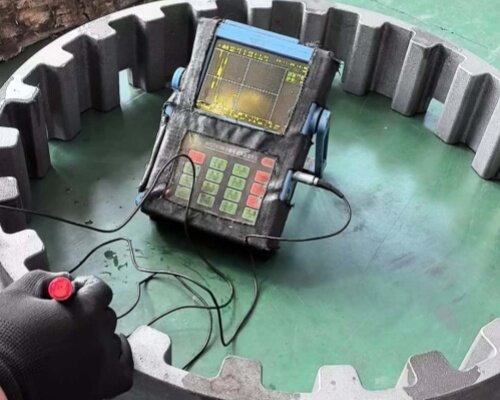

Quality Control

Quality & Service

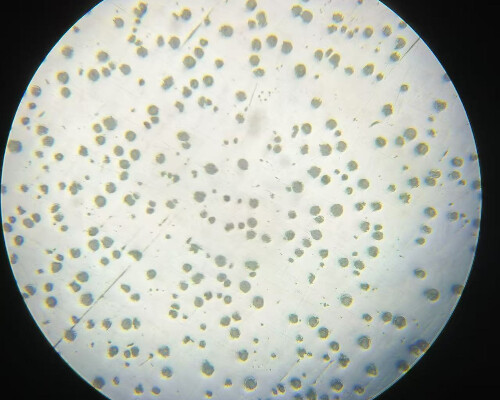

The molding machine is used to spray 200 mesh sand into the mold to make the sand shell for casting, which needs to be kept warm for 7-12 hours after casting.

Advantages: The rough castings have high precision, small machining allowance, and can be mass-produced quickly.

Disadvantage: The molds are expensive and are not suitable for large-scale castings or small-batch castings.