| 丨 |

PRODUCT CENTER Ningguo Keboer Intelligent Machine Tool Co., Ltd. |

Casting products – Machine base

Material: Gray iron 300 Process: Resin sand process Weight: 6850Kg

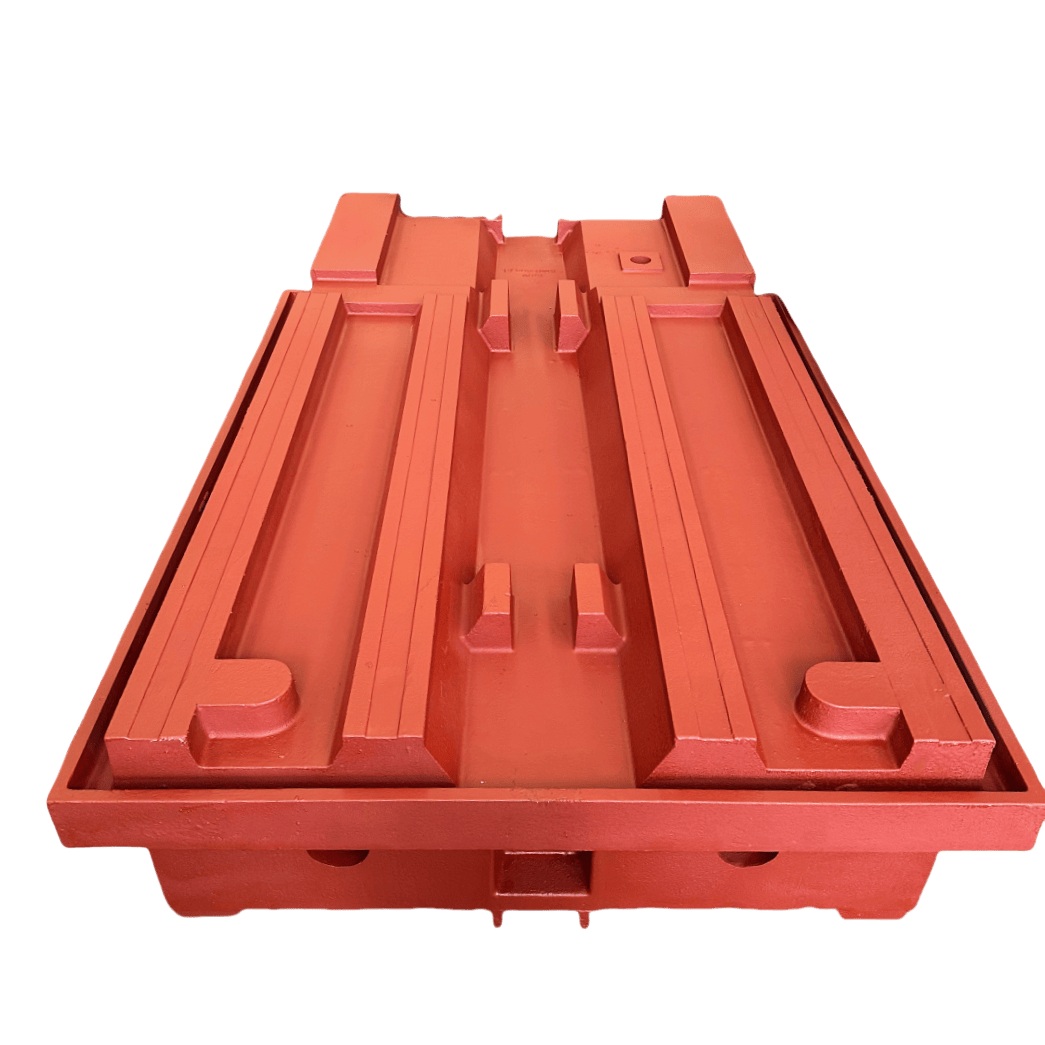

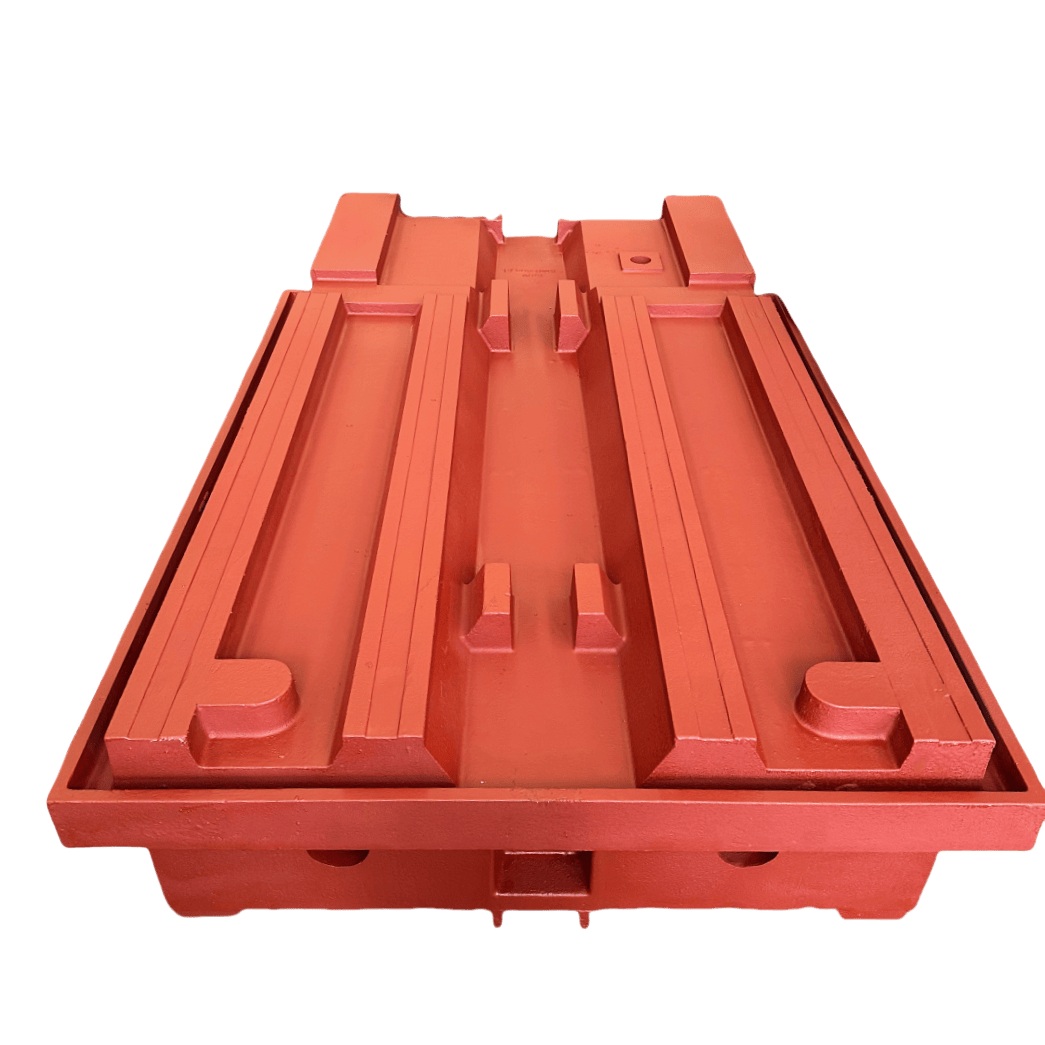

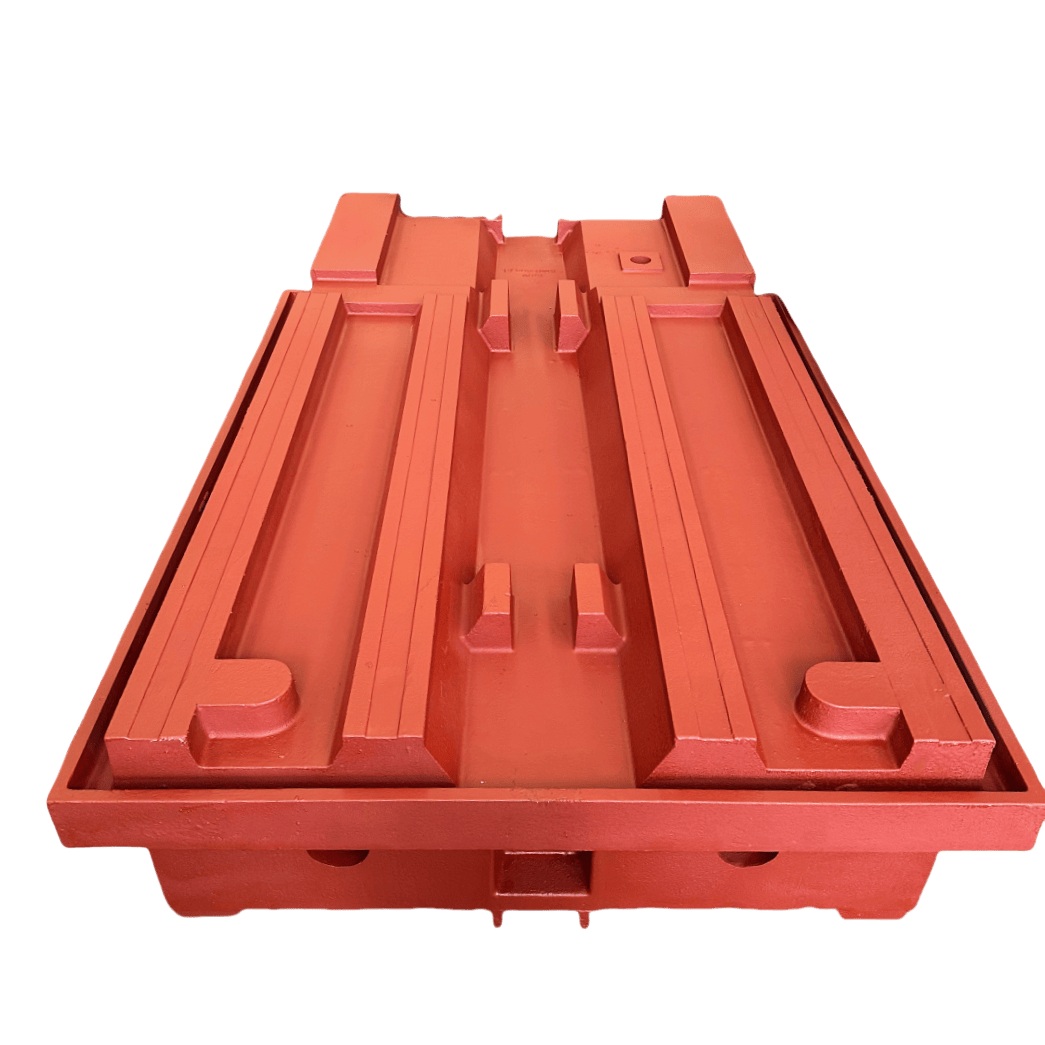

Machine table casting

Material: Gray iron HT300 Process: Coated sand process Weight: 100-300Kg

Grinding machine-base

Material: Gray iron 300 Process: Resin sand process Weight: 553Kg

CNC machine tools – Base castings

Custom casting-headstock

Material: Gray iron 350 Process: Coated sand process Weight: 370Kg

Casting products – Machine base

Material: Gray iron 300 Process: Resin sand process Weight: 6850Kg

Machine table casting

Material: Gray iron HT300 Process: Coated sand process Weight: 100-300Kg

Grinding machine-base

Material: Gray iron 300 Process: Resin sand process Weight: 553Kg

CNC machine tools – Base castings

Custom casting-headstock

Material: Gray iron 350 Process: Coated sand process Weight: 370Kg

Casting products – Machine base

Material: Gray iron 300 Process: Resin sand process Weight: 6850Kg

KEBOER

Reliable and stable casting supplier

ABOUT US

Ningguo Keboer Intelligent Machine Tool Co., Ltd. is a professional manufacturer of gray iron and ductile iron castings for bed, machine tools, air pressure pump bodies, casings, Construction machinery casting, agricultural machinery casting and other machinery industries, and has passed the quality management system ISO 9001:2015

High stability cast iron products, OEM/ODM metal casting manufacturers

Customized metal casting products, our long-term and stable supply of gray iron and ductile iron parts, using furan resin sand process to produce large castings (200Kg-10000Kg), machine tool castings, construction machinery castings, reducer castings, and other large castings and so on. The use of coated sand process to produce batches of small and medium-sized castings (1Kg-200Kg) precision castings, pump body castings, valve castings, flange castings, shell castings and so on.

SERVICES

SERVICES

Our precision iron casting process begins with selecting high-grade materials. We utilize grey iron casting for its excellent vibration damping... or ductile iron castings for high strength... As a specialized foundry for VMC parts, we then employ the furan resin sand casting for large parts process. This method creates strong, stable molds that ensure high dimensional accuracy and a fine surface finish.

After casting, components undergo an important aging process. This involves a combination of natural outdoor aging and controlled thermal treatment (annealing). This dual approach effectively relieves internal stresses from the casting and cooling phases, preventing future distortion and ensuring the long-term dimensional stability required for sustained machine accuracy.

Once the casting is stabilized, our in-house CNC workshop begins the machining process. We perform multi-stage machining, starting with roughing to remove bulk material, followed by fine machining to achieve final specifications. Our equipment, including large gantry machining centers, enables us to meet tight tolerances on all critical surfaces.

Before shipment, each component will undergo a comprehensive final inspection. We use coordinate measuring machines (CMMs) to verify the dimensional accuracy, which is of vital importance for the gray cast iron machine parts that are subjected to high stress.

CONTACT US

Fill this form and we'll get back to you soon.